Column navigation

Products

- Magnetic level gauge

- Magnetic level gauge

- Magnetic flap level gauge

- Glass plate level gauge

- Float level gauge

Contact Us

contacts:

mobile phone:4006643188

Telephone:13524563188

Email:13524563188@163.com

Address:Shanghai City

Industry News

Structural principle and working environment requirements of remote transmission magnetic float level gauge

- Release time:2025-01-10 17:23:16

Remote maglev level gauge may be unfamiliar to unfamiliar friends. But in the field of liquid level measurement, it is widely used and plays an important role in liquid level measurement, bringing great help to our work. In fact, a thorough understanding of liquid level gauges is a prerequisite for us to correctly utilize their functions.

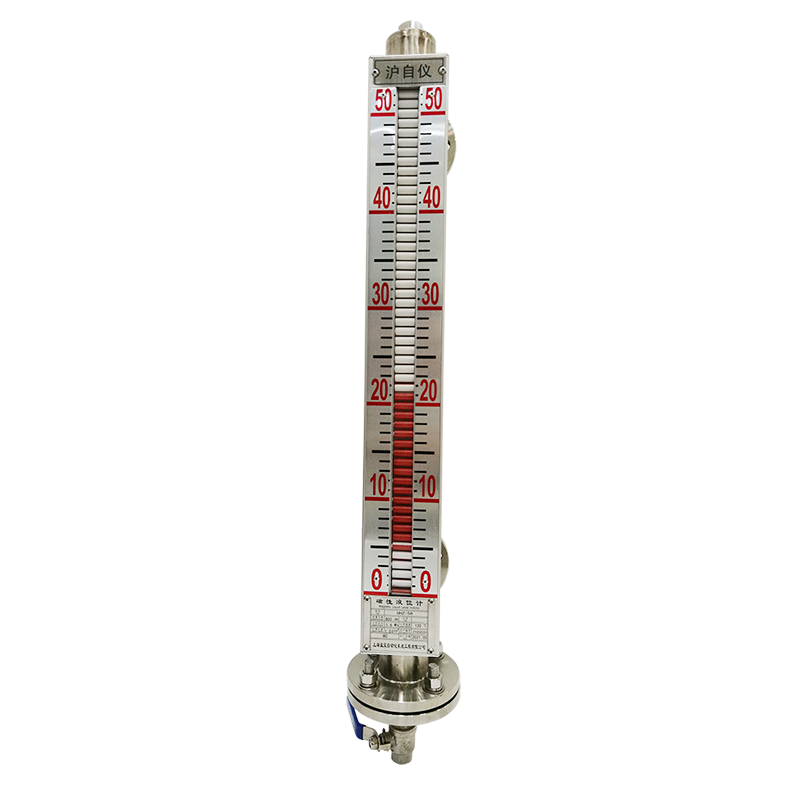

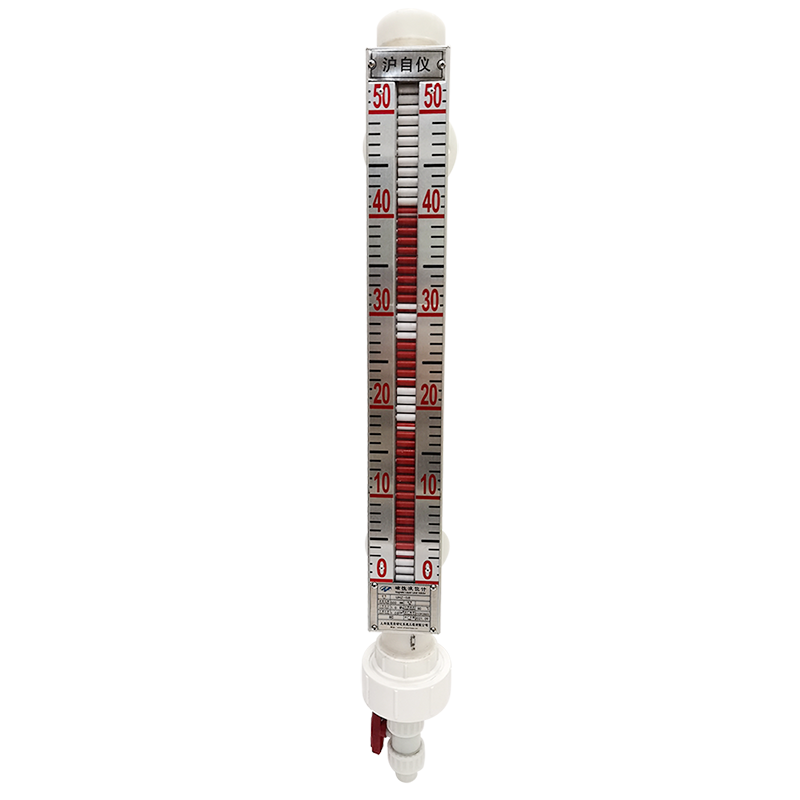

Remote transmission magnetic float level gauge is a measuring instrument that uses a magnetic float as a sensing element to reflect the measured liquid level or interface by displaying the magnetic coupling between the magnetic float and the magnet in the color column. Using the principle of connected pipes, ensure that the liquid level between the measured container and the measuring tube is equal. When the float in the measuring tube changes with the measured liquid level, the magnetic material in the float matches with the magnetic material in the color column displayed on the display panel, causing the color column to flip. White indicates no liquid, and red indicates liquid, thus achieving the value of locally displayed liquid level.

The structural principle and working environment requirements of remote magnetic float level gauge.

It has the advantages of intuitive display, eye-catching, wide viewing angle, compact and reasonable structure, safety and reliability, no "running, emitting, dripping, leaking" phenomenon, small maintenance volume, and low maintenance cost., And its indication function does not require additional power supply, even if the power supply fails, it will not affect the liquid level observation, making it an ideal liquid level detection instrument.

Not only can on-site display be achieved, but also the measured liquid level signal can be remotely transmitted to the corresponding centralized management control center through standard 4-20mA industrial signals, achieving remote centralized observation and control management. Remote magnetic float level gauges are widely used, but in order to optimize measurement performance, we still need to consider all working conditions and environments. Only by meeting the ideal measurement requirements of the magnetic float level gauge can the level gauge output ideal measurement data for us. So what are its requirements for the working environment?

1. Temperature. The temperature referred to here refers to the temperature of the object being measured, such as measuring the liquid level of a storage tank, which is the temperature inside the tank. We know that the working principle of remote magnetic float level gauges is to use magnetism, which depends on the key components of the float. The float comes into contact with the medium, and there is magnetic steel working inside the float. Excessive temperature often weakens or even eliminates the magnetism of the magnetic steel in the float. If the adaptive temperature of the float does not match the actual temperature, it will cause the magnetic stability of the float, or even the float will lose its magnetism and cannot be measured. It is related to the procurement cost of remote magnetic float level gauges and is also a key point in achieving cost-effectiveness in our procurement and selection work.

Secondly, pressure. This refers to the high pressure around the medium and the medium inside the equipment, which is the pressure inside the connecting pipe between the measured container and the remote magnetic float level gauge. Pressure is an important parameter that does not affect the thickness of the flange, but also affects the diameter of the float and the thickness of the main steel pipe. Is it necessary to support the pressure resistance of the float. If the pressure resistance of the float does not match the actual working pressure and the actual strength is much greater than the float's endurance, it is likely to be crushed and scrapped directly.

Thirdly, the chemical properties of the medium, commonly referred to as the degree of corrosiveness. This is an important environmental requirement. If the corrosiveness of the measuring medium is high, the contact medium material used to manufacture the level gauge should be corrosion-resistant. For example, 304 stainless steel is generally corrosion-resistant, 316L is slightly higher, and there are also PP corrosion-resistant and PTFE lined corrosion-resistant stainless steels. It also helps us to fully understand the economic characteristics of the medium, save the procurement cost of remote magnetic float level gauges, and optimize cost-effectiveness.

- Previous article:There's nothing more

- Next article:What are the types of liquid level gauges?