Column navigation

Products

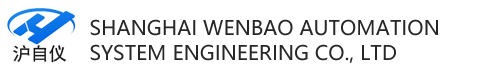

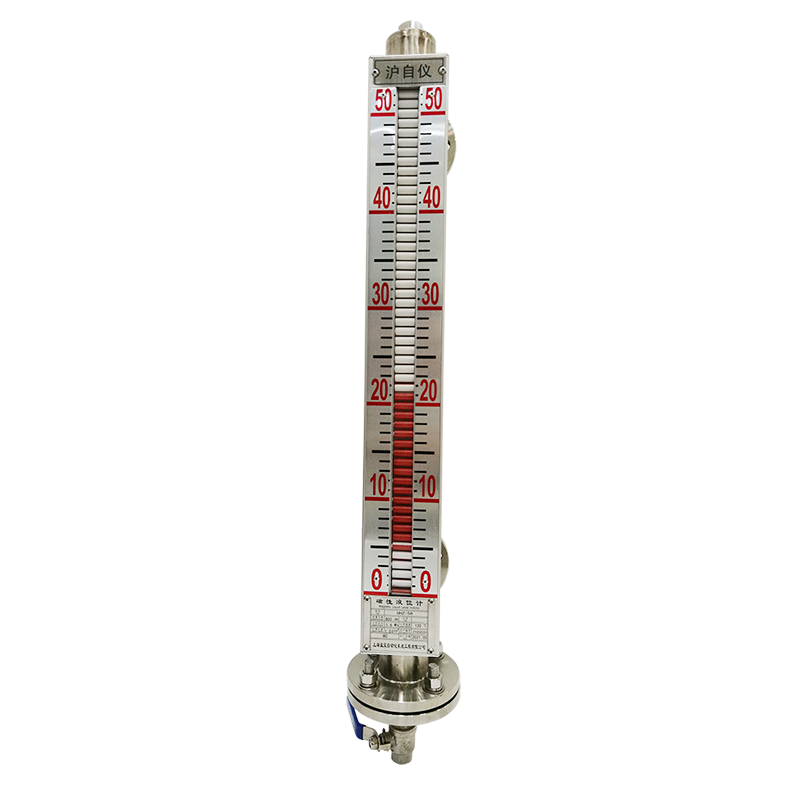

- Magnetic level gauge

- Magnetic level gauge

- Magnetic flap level gauge

- Glass plate level gauge

- Float level gauge

Contact Us

contacts:

mobile phone:4006643188

Telephone:13524563188

Email:13524563188@163.com

Address:Shanghai City

Stainless steel diaphragm pressure gauge

Diaphragm pressure gauges are mainly used in processes such as petrochemicals, alkali production, chemical fibers, pharmaceuticals, and food. They consist of a universal pressure gauge, connecting body, and diaphragm isolator. Used when measuring media with strong corrosion, high temperature, high viscosity, easy crystallization, easy solidification, and solid floating particles.

application

Diaphragm pressure gauges are mainly used in processes such as petrochemicals, alkali production, chemical fibers, pharmaceuticals, and food. They consist of a universal pressure gauge, connecting body, and diaphragm isolator. Used when measuring media with strong corrosion, high temperature, high viscosity, easy crystallization, easy solidification, and solid floating particles.

principle

When the pressure P of the measuring medium acts on the diaphragm, the diaphragm deforms and compresses the sealing fluid of the pressure measuring system of the pressure instrument, forming a pressure of P - △ P. When the rigidity of the diaphragm is small enough, Δ P is also very small, and the pressure formed by the pressure measuring system of the pressure instrument is close to the pressure of the measured medium.

The Temperature Effect of Diaphragm Gauge

The temperature effect of a diaphragm pressure gauge is related to the expansion coefficient of the sealing fluid, the stiffness of the diaphragm plate, and the temperature of the compressed area. When the instrument is used with a temperature deviation of 20 ± 5 ℃, the maximum change rate of the displayed value affected by temperature should not exceed 0.1% ℃ for rigidity and 0.1 ± 0.025L% ℃ for flexibility (remote connection) (L-pressure transmission conduit length m). When making diaphragm pressure gauges, attention should be paid to selecting the corresponding sealing working fluid according to different usage environments.