Column navigation

Products

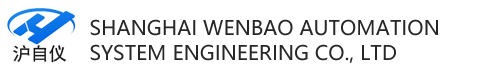

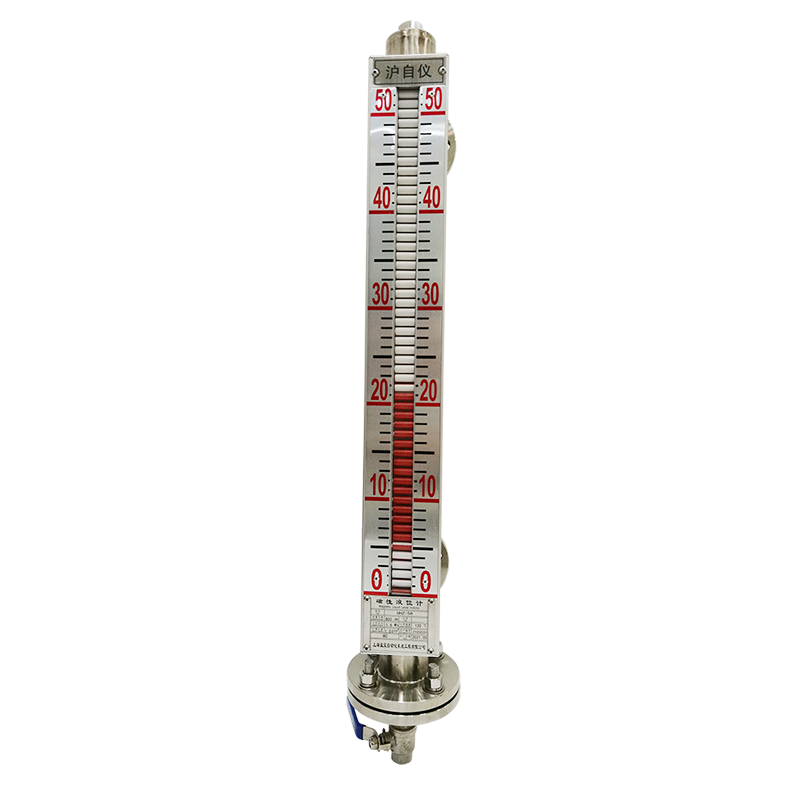

- Magnetic level gauge

- Magnetic level gauge

- Magnetic flap level gauge

- Glass plate level gauge

- Float level gauge

Contact Us

contacts:

mobile phone:4006643188

Telephone:13524563188

Email:13524563188@163.com

Address:Shanghai City

Explosion proof thermocouple

Industrial explosion-proof thermocouple is a temperature sensor widely used in chemical industry automation systems. Through temperature sensors, explosion-proof thermocouples can convert the temperature parameters of the controlled object into electrical signals and transmit them to display instruments, recorders, and regulators to detect, adjust, and control the system.

Industrial explosion-proof thermocouple is a temperature sensor widely used in chemical industry automation systems. Through temperature sensors, explosion-proof thermocouples can convert the temperature parameters of the controlled object into electrical signals and transmit them to display instruments, recorders, and regulators to detect, adjust, and control the system.

In chemical plants, various flammable and explosive chemical gases are often present on the production site. Using ordinary thermocouples is very unsafe and can easily cause environmental gas explosions. Therefore, explosion-proof thermocouples must be used as temperature measuring instruments in these situations. Our company's explosion-proof thermocouple products are suitable for use in places with explosive gas hazards within the EXd Ⅱ CT6 temperature group range.

working principle:

If a closed circuit is composed of two homogeneous conductors (thermoelectric electrodes) with different compositions, and there is a temperature gradient at both ends, current flows through the circuit, resulting in a thermoelectric potential between the two ends.

Explosion proof principle:

By utilizing the principle of gap explosion-proof, design junction boxes and other components with sufficient strength, and seal all parts that can generate sparks, arcs, and dangerous temperatures inside the junction box. When an explosion occurs inside the chamber, it can be extinguished and cooled through the gap between the joint surfaces, preventing the flame and temperature after the explosion from being transmitted outside the chamber.

- Previous:Wear resistant thermistor

- next:Hot sleeve thermocouple